Improved cyber-physical product development reduces technology integration costs, helps manage technology risk, and reduces cost over the entire software life-cycle. FMI technology can improve efficiency and reduce integration time of collaborative cyber-physical development and can better protect intellectual property shared in the collaboration. The Functional Mockup Interface (FMI) is an open standard for model interfacing providing a well-defined methodology for exchanging simulations and models of subsystems for integration with other simulations and models. ADEPT has support for both FMI Co-simulation and FMI Model Exchange.

Challenges of collaboration for Cyber-Physical Product Development

A cyber-physical product development process requires integration of multiple virtual and real assets to verify the combined system support of functional requirements. Simulation models may be developed in various physics domains, be solved with different methodologies or even be provided within tools specialized for that domain. The models may be developed by multiple engineering departments or by external suppliers having expertise in their system’s domain. A supplier is usually required to supply a virtual design of their system for integration testing, and in order to protect their intellectual property would provide the design as a compiled object. The objective for the systems integrator or OEM is to most efficiently integrate the various simulation articles into a unified simulation for design and development activities. Navigating the various implementations of virtual systems is one of the main challenges for the systems integrator.

Functional Model Interface Concept

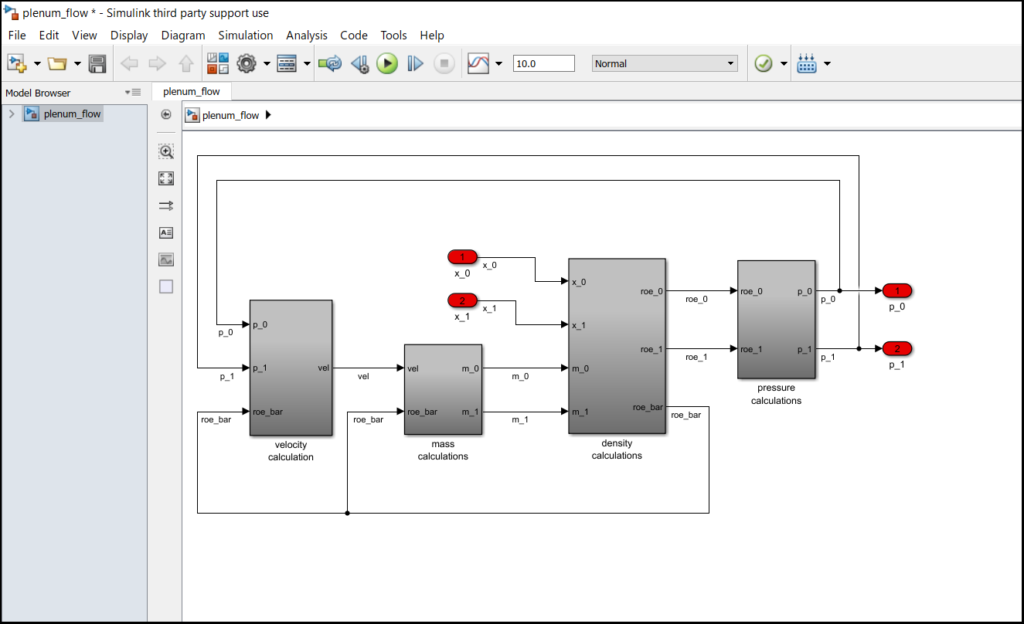

The Functional Mockup Interface (FMI) standard enables compatibility between different simulation tools and provides a generic model interface for embedded devices and simulators. The interface defined by the FMI is implemented by an executable called a Functional Mockup Unit (FMU).

FMI supports two methods for integration: model exchange and co-simulation. With model exchange the FMU is exported and supported/imported by the main simulation environment (or master simulator) containing the solvers for the FMU; with co-simulation the FMU is synched to the master simulator as a slave and the FMU contains its own solver. Conceptually, at each communication step, an FMU for model exchange provides a model for evaluation while an FMU for co-simulation provides the results of evaluation from the current communication step. An FMU for co-simulation may be provided as a stand-alone component (e.g. a dynamic link library), or alternatively as a model within a separate simulation tool. Both approaches are covered by the FMI standard. Multiple instances of an FMU may be created by the master simulator. Each FMU controls its own level of openness.

An FMU is essentially an application programming interface and its semantics, xml schema, describes the model structure and capabilities. The FMU is packaged as a zip file containing the model implementation in source or binary, the model description in xml, and any additional data and functionality. An FMU may contain multiple implementation binaries in order to support Linux and Windows operating systems, as well as 32-bit and 64-bit architectures.

Benefits of FMI/FMU

FMI can reduce costs for both a supplier/model developer and for the OEM/model integrator. Consider that FMI is fully supported as an open standard that is actively maintained and improved via the Modelica Association. FMI is supported by many popular simulation packages, with many FMI examples freely available, and at least one software development kit available from QTronic to produce a C-based FMU. The FMI standard is widely accepted by the simulation community. Without a standard model interface definition, a single supplier may be required to maintain multiple interfaces for models provided to multiple OEMs; conversely an OEM or systems integrator may be required to integrate models from various suppliers each having its own interface. Miscommunicated interface definitions of variable types, expected accuracies, or engineering units, have been the cause for wasted hours spent debugging and in the worst case, for product safety issues. Adopting FMI for sharing models has the potential for reducing effort, improving model interface documentation, ensuring interface specifications are satisfied, and improving security of intellectual property between organizations.

Benefits of ADEPT Framework and FMI/FMU

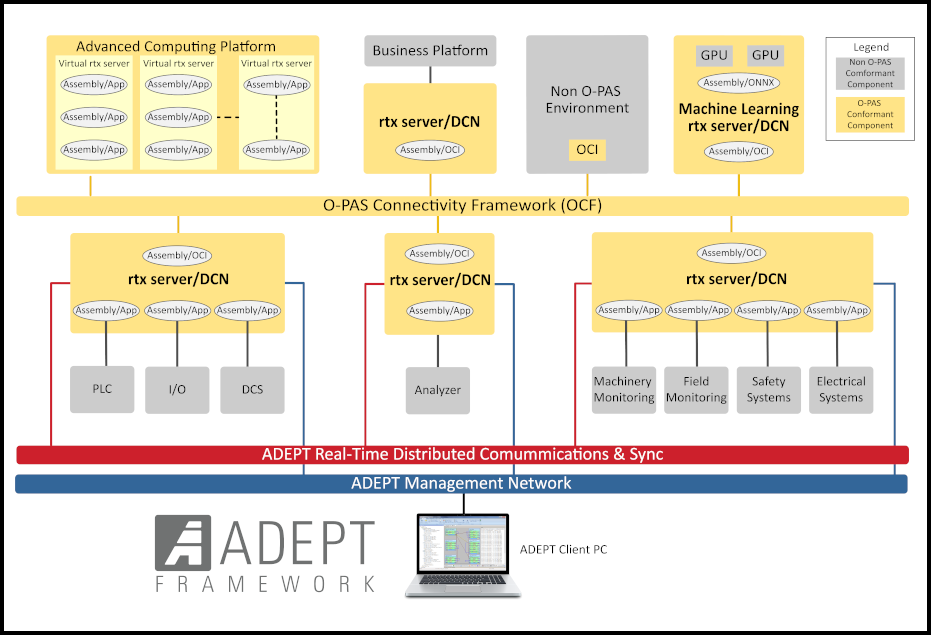

ADEPT supports data-centric frameworks for efficient Model Based Systems Engineering. With tools and services for integrating simulation models, Hardware in-the-loop simulations, software assets, and human and machine interfacing, ADEPT provides an excellent computing environment for systems integration, verification and validation. ADEPT supports functional testing; provides data acquisition; supports simulation control and probes; records, analyzes, and generates reports of test evidence; and offers a fully programmable interface via Python. With an open architecture, layered on commercial off-the-shelf hardware, ADEPT minimizes costs and avoids obsolescence.

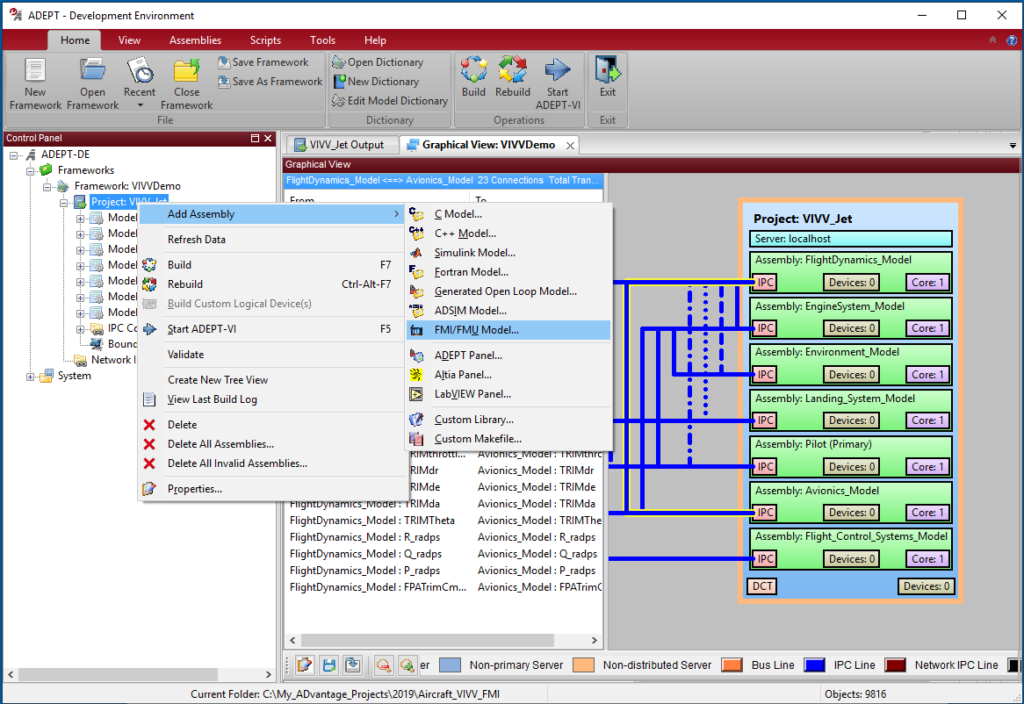

In an ADEPT framework, models implemented in various modeling tools can be integrated with other FMU’s for deployment to a local Windows or Linux host system or to industrial real-time Linux servers. Figure 1 shows a data-centric framework for aircraft system integration and verification being integrated with an FMU via ADEPT-DE.

Figure 1: Adding an FMU to an ADEPT Framework

FMI Standard Adoption

The FMI standard was initiated in the automotive community to improve exchange of simulation models between suppliers and OEMs; however, it is now applied by many non-automotive organizations. Integration and verification of aircraft development is an obvious application for using FMI. Aircraft systems span multiple physics domains and simulation models for aircraft integrated simulation may include high-fidelity models of aerodynamic, thermal, hydraulic, power, and elastic physics. Co-simulation with multiple simulation tools is often preferred for design and optimization studies of a system with multiphysics subsystems to support high-fidelity representations of the subsystems.

Conclusion

Model integration is a key activity in cyberphysical product development, supporting design and optimization analysis, verification of system function, and even product maintenance and upgrades. For complicated systems, development efforts are cooperative and involve multiple computer systems, various simulation tools, multiple suppliers, and multiple physics domains. Adoption of an open standard for simulation integration such as FMI can make this aspect of product development more manageable and cost effective. The ADEPT Framework makes it easy to integrate FMI models with other cyberphysical product development assets, enabling significant efficiency and cost savings for integration, verification and validation efforts for projects of any size.

What capabilities can the ADEPT Framework enable for your projects? Contact your local ADI representative today to see how the ADEPT Framework can improve the efficiency of your cyberphysical product development activities.